Welcome to Shanghai Zhongyou Industrial Co., LTD. Website!

Welcome to Shanghai Zhongyou Industrial Co., LTD. Website! Welcome to Shanghai Zhongyou Industrial Co., LTD. Website!

Welcome to Shanghai Zhongyou Industrial Co., LTD. Website!Current Location:首页 > Product center > Air (water) cold water unit and low temperature unit > Water cooled screw chiller > LSB1180DLSB series high efficiency (energy saving) type water cooling screw chiller

Brief description:LSB series high-efficiency (energy-saving) water-cooled screw chiller is a new generation of screw chiller designed and developed by the company with strong product research and development ability and many years of experience in designing and producing piston chiller, integrating the advantages of similar products at home and abroad。The product tracks the development trend of The Times, combines the characteristics of high reliability, high efficiency, high automation and energy saving and environmental protection together, is a more convenient and reliable green central air conditioning host, which can be applied to air conditioning and ice storage conditions at the same time。The product is widely used in shopping malls, hotels, theaters, hospitals, large factories and high-rise buildings need air conditioning or ice storage places

Product model:LSB1180D

Product model:LSB1180D Nature of manufacturer:manufacturer

Nature of manufacturer:manufacturer Update time:2024-05-15

Update time:2024-05-15 Number of enquiries: 1053

Number of enquiries: 1053Product classification

Product CategoryRelated article

Related ArticlesDetailed introduction

| 品牌 | ZHONGYOU/ Zhongyou |

|---|

How it works:

LSB series high efficiency (energy saving) type water cooling screw chillerIt is a new generation of screw chiller designed and developed by the company with strong product research and development ability and many years of experience in designing and producing piston chiller, integrating the advantages of similar products at home and abroad。The product tracks the development trend of The Times, combines the characteristics of high reliability, high efficiency, high automation and energy saving and environmental protection together, is a more convenient and reliable green central air conditioning host, which can be applied to air conditioning and ice storage conditions at the same time。The product is widely used in shopping malls, hotels, theaters, hospitals, large factories and high-rise buildings that need air conditioning or ice storage, and can also be used as a cold source host for the process of electric power, chemical industry, medicine and other industries。

This product complies with GB/T 18430.1-2001 "Steam compression Cycle cold water (heat pump) units for industrial and commercial use and similar cold water (heat pump) units" regulations。 At the same time, it meets the secondary energy efficiency grade standard stipulated in GB19577-2004 "Energy efficiency Limit Value and energy efficiency grade of Chiller"。

Cooling capacity:100KW-3860KW

Scope of application:1000m2-35000m2 of shopping malls, office buildings, hotels, theaters, restaurants, entertainment and other buildings。

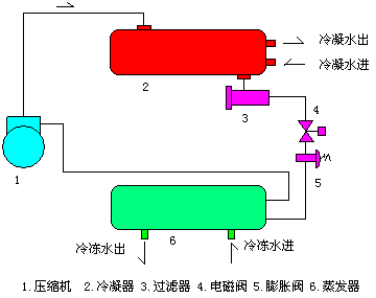

Working principle图:

Unit features:

1. 螺杆式Compressor:

Semi-enclosed twin screw refrigeration compressor。

High efficiency 5:6 asymmetric tooth type twin screw。

With four-stage capacity adjustment or stepless capacity adjustment。

High-precision SKF, FAG zero clearance bearings。

The built-in oil is filtered by double-layer method, the oil filtering effect is good, and the heat exchanger can play the best effect。

The motor adopts high efficiency silicon steel and special groove design, equipped with internal and external omnidirectional design cooling runner and inlet and outlet pressure drop minimization design, so that the compressor efficiency is very high。

Built-in differential oil supply lubrication system to reduce wearing parts。

The design of axial continuous gas transmission type exhaust chamber reduces vibration and noise。

2. 电气控制:

Electronic control components and industrial grade PLC programmable controller。

Large screen liquid crystal display, display the operation parameters of the control equipment。

Automatic protection functions such as high and low pressure protection, oil level protection, exhaust overheating, motor overheating, overcurrent protection, phase deficiency, reverse phase protection, water cut-off protection, antifreeze protection, etc., ensure the high reliability of product operation。

It has control functions such as equal wear switching, cumulative running time recording, fault display and lock, current temperature display, historical temperature trend and record, timed on and off, etc. At the same time, it can provide a standard standby interface with remote control function according to user requirements, ensuring a high degree of automation of product operation。

3. Heat exchanger:

The high efficiency shell and tube heat exchanger designed by computer optimization realizes the optimization of parameters, ensures the best heat transfer effect, and ensures that the unit has a good energy efficiency ratio in a wide area。

The heat exchanger adopts the design of increasing the dirt coefficient on the water side to ensure that the cold capacity of the unit does not decay during the long-term operation。

4. Thermal expansion valve:

The use of precise control thermal induction expansion valve, so that the unit can play the highest efficiency at full load or partial load, so that the energy efficiency ratio is increased by 5% ~ 10%。

5. Energy saver:

The use of a good level of stainless steel plate heat exchanger and a shell and tube economy with independent intellectual property rights can effectively improve the cooling capacity of 15%-20%。

6. Reliable and complete testing:

After the assembly is completed, the air pressure leak detection test is strict。

Pressure retention test lasting 24h。

Multi-system (including dual system) unit 24h separate cavity pressure holding test。

Full load test with fluorine。

7. Convenient transportation, installation and commissioning:

All products are delivered with fluorine. After the equipment is installed in place, connect the water pipe and power line, and press the power button to realize the normal operation of the product。

The small size greatly reduces the equipment room space required for installation。

8. High energy efficiency, widely used:

Developed according to a lot of design experience, the energy efficiency ratio of the unit is higher。

The cooling capacity of a single machine can reach up to 3410KW, which makes the screw type chiller widely used in large buildings。

9.Technical parameters:

型号 | LSB-1180D | |

Cooling capacity (KW) | 1180 | |

compressor | 类型 | Semi-enclosed screw compressor |

台数 | 2 | |

Rated power (KW) | 253.2 | |

refrigerant | 名称 | R22 |

Charge volume (kg) | 238 | |

evaporator | 类型 | Dry evaporator |

Effluent temperature (℃) | 7 | |

Inlet water temperature (℃) | 12 | |

Circulating water quantity (m³/h) | 203 | |

Nozzle size (ND) | 2-DN200 | |

Pressure dropkPa) | <90 | |

condenser | 类型 | Horizontal shell and tube type |

Effluent temperature (℃) | 35 | |

Inlet water temperature (℃) | <30 | |

Circulating water quantity (m³/h) | 247 | |

Nozzle size (ND) | 4-DN150 | |

Pressure dropkPa) | <90 | |

Total unit power (KW) | 253.2 | |

Overall dimension(Length * width * height) mm | 4620*1500*2288 | |

重量(KG) | 6000 | |

Product consulting

Scan wechat